Following the joint U.S-Soviet Apollo-Soyuz Test Project mission of July 1975, Launch Complex 39a was modified to support Space Shuttle operations. For the Space Shuttle, two permanent service towers were installed at each pad for the first time, the Fixed Service Structure and the Rotating Service Structure. On April 12, 1981, Shuttle operations commenced at Pad A with the launch of Columbia on STS-1. After 23 more successful launches from A, the first Space Shuttle to lift off from Pad B was the ill-fated Challenger in January 1986. Pad B was designated for the resumption of Shuttle flights in September 1988, followed by the reactivation of Pad A in January 1990.

Just as for the first 24 shuttle flights, Launch Complex 39a supported the final shuttle flights, starting with STS-117 in June 2007 and ending with the retirement of the Shuttle fleet in July 2011. Prior to the SpaceX lease agreement, the pad remained as it was when Atlantis launched on the final shuttle mission on July 8, 2011, complete with a mobile launcher platform.

82 of the 135 launches of the Space Shuttle occurred from Launch Complex 39a, including Columbia STS-107 in 2003.

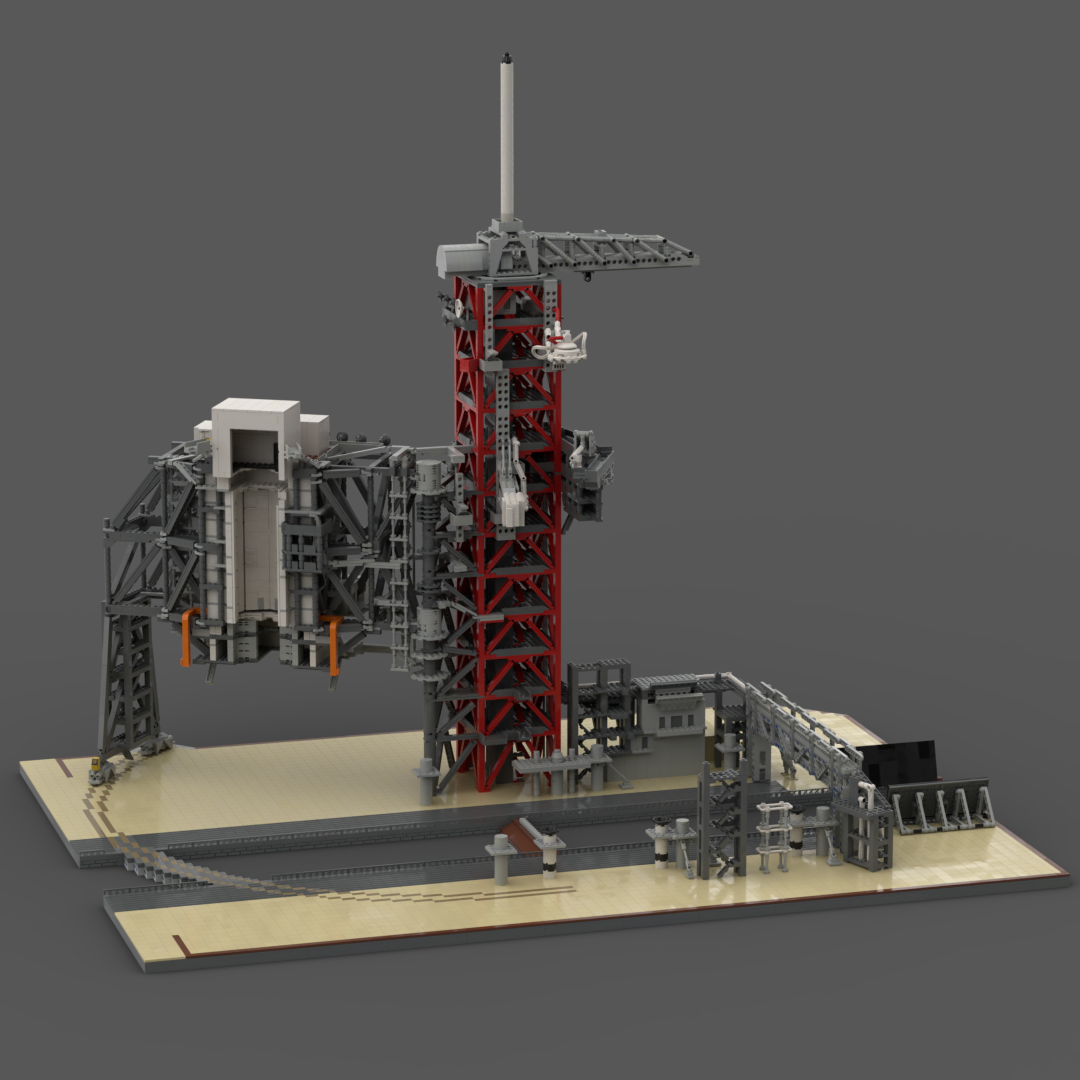

Fixed Service Structure (FSS)

The FSS is each pad’s most prominent feature, standing 347 feet from ground level to the tip of the lightning mast. The 80-foot tall fiberglass mast supports a one-inch stainless steel cable that starts from an anchor south of the FSS, angles up and over the mast, and then extends back down to a second anchor to the north. Below the lightning mast is a hammerhead crane used for pad hoisting operations. The FSS is equipped with three swing arms that provide services or access to a Shuttle on the pad. They are retracted when not in use. There are 12 floors on the FSS, positioned at 20-foot intervals. The first is located 27 feet above the pad surface. The FSS also provides an Emergency Egress System for astronauts.

Orbiter Access Arm

This is the lowermost arm, located 147 feet above the pad surface. It allows personnel to enter the orbiter crew compartment. The outer end of the access arm features an environmental chamber or “white room” that mates with the orbiter and holds six persons. The arm remains in the extended position until seven minutes, 24 seconds before launch to serve as an emergency escape route for the flight crew. It is 65 feet long, 5 feet wide, and 8 feet high, and can be mechanically or manually repositioned in about 15 seconds in the event of a contingency.

External Tank Hydrogen Vent Umbilical and Intertank Access Arm

Also called the External Tank (ET) Gaseous Hydrogen Vent Arm System, at the 167-foot level, the 48-foot-long arm allows mating of the external tank umbilicals as well as contingency access to the external tank intertank compartment. The arm rotates 210 degrees to its extended position. The arm is retracted after umbilical/vent line mating, typically at about T minus five days, leaving the umbilical vent line connected to the external tank to support tanking and launch. The umbilical vent line provides continuous venting of the external tank during and after loading of the volatile liquid hydrogen. The vent line is disconnected from the vehicle at first motion and retracts vertically downward to a stored position.

ET Gaseous Oxygen Vent Arm

Attached between the 207- and 227-foot levels is a retractable arm and vent hood assembly. The arm truss section measures 65-feet long from tower hinge to vent hood hinge. The 13-foot wide vent hood also is known as the “beanie cap” (seen at top in photo on page 2). Heated gaseous nitrogen is pumped into the hood to warm the liquid oxygen vent system at the top of the external tank. This prevents oxygen vapors that are exiting the vent louvers from condensing water vapor in the surrounding air into potentially damaging ice. About two and a half minutes before launch, the vent hood is raised to clear the external tank, a 25-second procedure. The arm is retracted against the FSS at about one minute, 45 seconds before liftoff. It is not latched in the event there is a hold, in which case the arm can be re-extended and the beanie cap again lowered onto the external tank. The arm is latched when the solid rocket booster ignition signal is given at T minus 0 minutes.

Emergency Egress System

Located 195 feet above the ground, at the same level on the FSS as the Orbiter Access Arm, is the Emergency Exit, or Egress, System. It provides an escape route for personnel inside the orbiter or on the Orbiter Access Arm. The system includes seven baskets suspended from seven slidewires that extend from the FSS to a landing zone 1,200 feet to the west. Each basket can hold up to three people. A braking system catch net and drag chain slow and then halt the baskets sliding down the wire approximately 55 miles per hour in about half a minute. Also located in the landing zone is a bunker, with an M-113 armored personnel carrier stationed nearby.

Rotating Service Structure (RSS)

The RSS provides protected access to the orbiter for installation and servicing of payloads at the pad, as well as servicing access to certain systems on the orbiter. The majority of payloads are installed in the vertical position at the pad, partly because of their design and partly because payload processing can thus take place further along in the launch processing schedule. Spacelab and other large horizontal payloads are loaded while the orbiter is in an Orbiter Processing Facility high bay. The RSS is 102 feet long, 50 feet wide, and 130 feet high. It is supported by a rotating bridge that pivots about a vertical axis on the west side of the pad’s flame trench. The RSS rotates through 120 degrees —1/3 of a circle — on a radius of 160 feet. Its hinged column rests on the pad surface and is braced against the FSS. The RSS is retracted before launch.

The major feature of the RSS is the Payload Changeout Room, an enclosed, environmentally controlled area that supports payload delivery and servicing at the pad and mates to the orbiter cargo bay for vertical payload installation. Clean-air purges help ensure that payloads being transferred from the payload canister into the Payload Changeout Room are not exposed to the open air. The payload is removed from the canister and later installed inside the orbiter cargo bay using the Payload Ground Handling Mechanism (PGHM).

Five platforms are positioned at five levels to provide access to the payload when it is installed on the PGHM. Each platform has extendible planks that can be configured to accommodate a particular payload. Another feature of the RSS is the Orbiter Midbody Umbilical Unit, which provides access and services to the midfuselage portion of the orbiter. The unit is 22 feet long, 13 feet wide, and 20 feet high. It extends from the RSS at levels ranging from 158 feet to 176 feet above the pad surface and includes a sliding extension platform and a horizontally moving line-handling mechanism. The unit provides access to the midbody umbilical door. It is used to supply fluids to the orbiter’s power reactant storage and distribution system and payloads. Liquid oxygen and liquid hydrogen for the fuel cells are funneled through here, as are gases such as nitrogen and helium.

Also found on the RSS is the Hypergolic Umbilical System. Hypergolic fuel and oxidizer lines, as well as helium and nitrogen service lines, are carried from the FSS to the Space Shuttle Orbital Maneuvering System (OMS) pods via this umbilical system. It includes six manually operated and locally controlled umbilical handling units that are structurally attached to the RSS. The Hypergolic Umbilical System lines can be mated and demated from the vehicle very rapidly.

Flame Trench-Deflector System

The flame trench, built with concrete and refractory brick, bisects the pad at ground level. It is 490 feet long, 58 feet wide and 42 feet deep. The flame deflector system includes an inverted, V-shaped steel structure covered with a high- temperature concrete material five inches thick that extends across the center of the flame trench. One side of the “V” receives and deflects the flames from the orbiter main engines; the opposite side deflects the flames from the solid rocket boosters. There are also two movable deflectors at the top of the trench to provide additional protection to Shuttle hardware from the solid rocket booster flames.

LOX and LH2 Storage

Liquid oxygen (LOX) used as an oxidizer by the orbiter main engines is stored in a 900,000-gallon tank on the pad’s northwest corner, while the liquid hydrogen (LH2) used as a fuel is kept in an 850,000- gallon tank on the northeast corner. The propellants are transferred from the storage tanks in vacuumjacketed lines that feed into the orbiter and external tank via the tail service masts on the Mobile Launcher Platform. The liquid oxygen tank functions as a huge vacuum bottle designed to store the cryogenic fluid at a very low temperature — less than -297 degrees Fahrenheit. It is transferred to the pad by one of two main pumps capable of pumping 1,300 gallons per minute. The lighter liquid hydrogen is stored in a vacuum bottle located at the northeast corner of each pad. It must be kept at an even lower temperature than the LOX: minus 423 degrees F. To move the LH2 to the pad, a small amount of the liquid hydrogen is allowed to vaporize, and the gas pressure exerted from the top of the tank pushes the LH2 into the transfer lines.

Hypergolic Storage

The orbiter’s Orbital Maneuvering System and Reaction Control System burn monomethyl hydrazine as a fuel and nitrogen tetroxide as an oxidizer. These hypergolic fluids are stored in well-separated areas on the southwest and southeast corners of the pads, respectively. Transfer lines convey the fluids through the FSS to the Hypergolic Umbilical System located on the RSS, with its three pairs of umbilicals attaching to the orbiter. Pad Terminal Connection Room The Pad Terminal Connection Room is located on the west side of the flame trench, underneath the elevated hardstand. It is covered with as much as 20 feet of dirt fill. Housed here in a reinforced concrete room is the equipment that links elements of the Shuttle, Mobile Launcher Platform and the pad with the Launch Processing System headquartered in the Launch Control Center. Checkout, countdown and launch of the Shuttle are performed and controlled through the Launch Processing System.

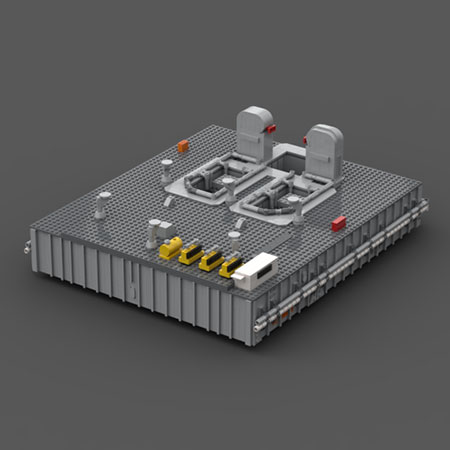

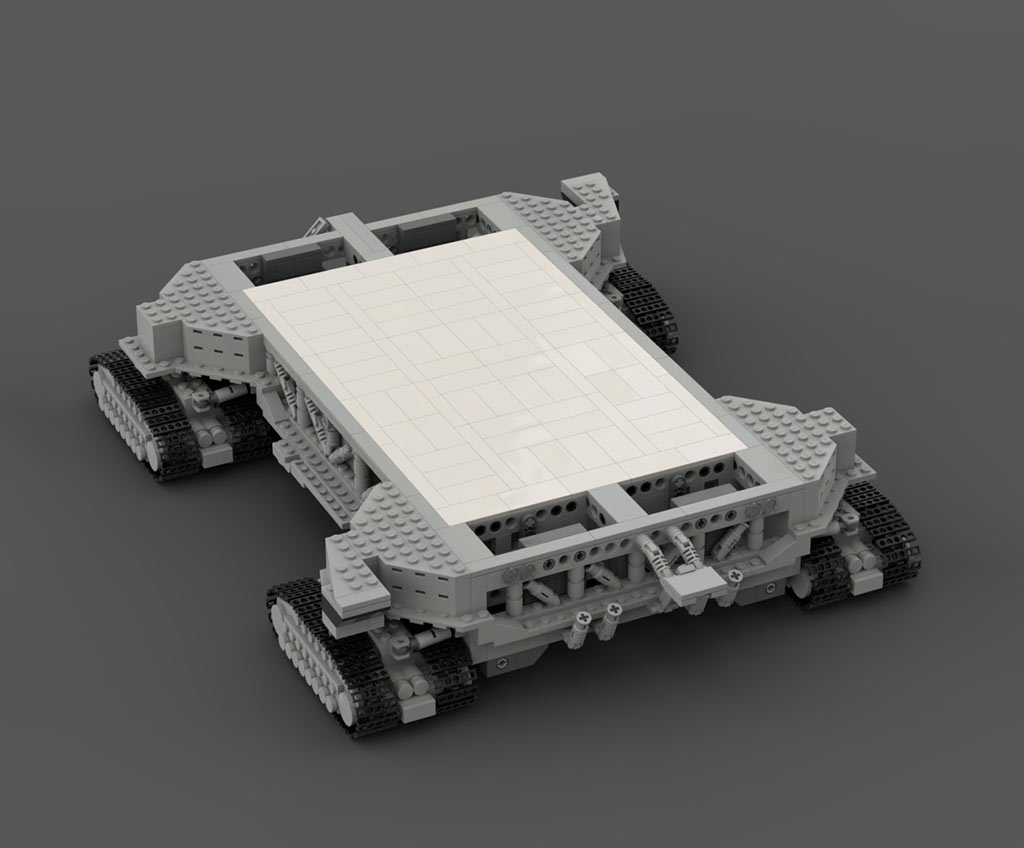

Launch Pad/MLP Interfaces

The Space Shuttle is brought to the pad atop the Mobile Launcher Platform (MLP) and Crawler-Transporter. The MLP is parked on pedestals permanently located at the pad and is the platform from which the Shuttle is launched. Several MLP systems interface with pad systems. These include the Sound Suppression System and the propellant transfer lines for the external tank. Helium and nitrogen, as well as ground electrical power and connections for vehicle data and communications, also are established through the tail service masts of the MLP. The Space Shuttle Main Engine Hydrogen Burnoff System, located inside the tail service masts, eliminates free hydrogen present prior to main engine ignition. Hydrogen vapors are exhausted into the main engine nozzles during the start sequence; if ignited when the main engines ignite, a small explosion could ensue, which might damage the engine bells. The six hydrogen burnoff pre-igniters are initiated just before main engine start. They throw off thousands of hot, luminescent balls into the area below the engine bells, igniting the free hydrogen and precluding a rough combustion when the main engines start.

Sound Suppression System

A Sound Suppression System was installed on the pads and MLP to protect the orbiter and its payloads from being damaged by acoustical energy reflected from the MLP during liftoff. Water stored in a 290- foot-high, 300,000-gallon tank on the northeast side of the pad is released just prior to main engine ignition and flows by gravity to special MLP outlets, including six 12-foot-high quench nozzles, or “rainbirds.” Nine seconds after liftoff, peak flow rate is 900,000 gallons per minute. A water spray system provides a cushion of water which is directed into the flame hole directly beneath each booster. A series of water bags stretched across the flame holes, providing a water mass to dampen the reflected pressure pulse, supplements this effort. Used together, this water barrier blocks the path of the reflected pressure wave from the boosters, greatly decreasing its intensity. The system reduces acoustical levels within the orbiter payload bay to about 142 decibels, below the design requirement of 145 decibels.

Designer Notes

This model works with this Mobile Launch Platform and this Space Shuttle or this Space Shuttle.

I have two versions of the instructions. First the “anno 1980 – v2”, which is finished for now. But since the color scheme changes completely to the next model, I’ve also uploaded the instructions for the “anno 1990 – v0.1” variant. It is the same model, but I changed all the colors to LBG instead of red and DBG as the 1980 version has. This is only done as a service for anyone that feels like they want to build a later version of the complex, but don’t want to wait for me or anyone else to complete the rest of the structures needed for the 1990 build. Use it with care, it is in no way finished.

I have also been busy with making some alternative builds for the base and the northern pipe bridge. Since the original design for these two parts of the complex are quite expensive to build, I created alternatives that should be simpler and cheaper to build. If you want to use these extra builds, you must create the instructions yourself.

Part count: 13672 bricks, 576 lots.

| Unit |

width |

length |

height |

| Studs |

115.0 |

144.0 |

122.2 |

| Centimetres |

92.0 |

115.2 |

97.8 |

| Inches |

36.2 |

45.4 |

38.5 |